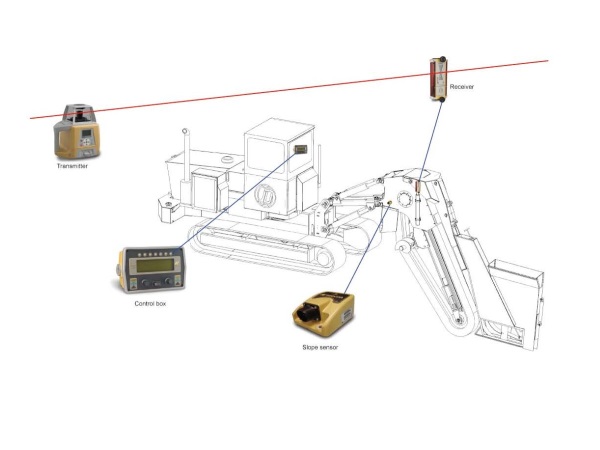

Laser Machine Control

A combination of reliable, ruggedized components, unmatched innovation and performance

For more than 50 years laser systems represented a great leap in grade control. Completely user-friendly, user-definable, they are flexible enough to apply even the most difficult jobs. The laser plane itself will present the wanted slope and elevation to the operator via indicator lights or even send corrections to the machine's hydraulics. With a laser machine control system, the operator is really in control.

Advantages of a laser control system on a trencher or plow are:

1. Precision and Accuracy: Laser control systems ensure precise depth and grade control, which is crucial for effective drainage. The system automatically adjusts the digging device to maintain the desired elevation and slope.

2. Increased Efficiency: By maintaining consistent trench depth and alignment, laser control systems reduce the need for manual adjustments, saving time and increasing productivity.

3. Improved Quality: The accuracy provided by laser control results in higher quality work, with fewer errors and rework required.

4. Enhanced Operator Ease: Operators can rely on the laser system to maintain the correct settings, reducing fatigue and allowing them to focus on other aspects of the job.

5. Versatility: These systems can be used in various conditions and terrains, making them adaptable to different job sites.

A laser control system can include a slope sensor and tilt sensor

6. Slope sensor: Suitable to control the steady slope of the pipe box

7. Tilt sensor: Guarantee for a precise adjustment of the machine’s angle, ensuring consistent trench depth and alignment, even on sloped or uneven terrain.